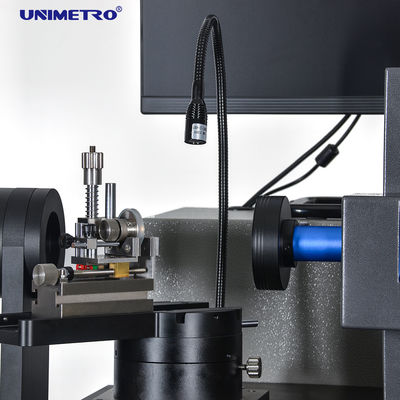

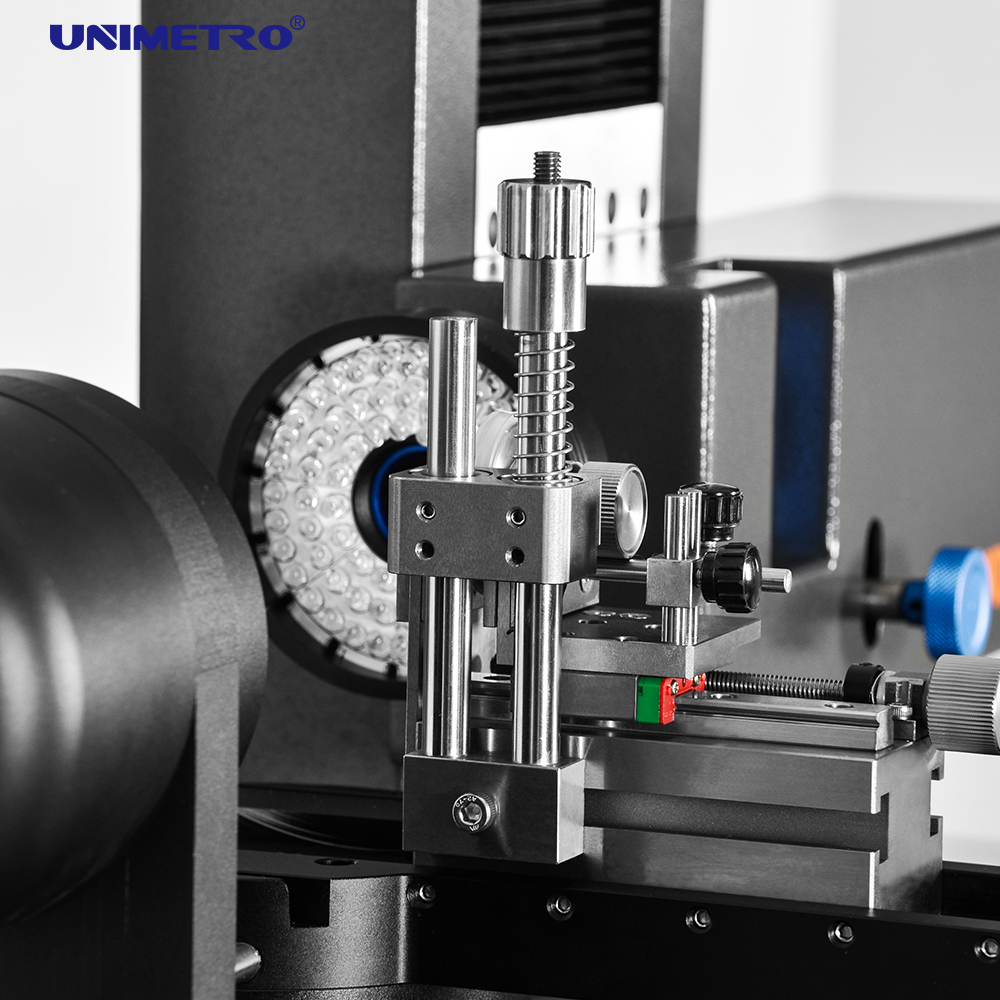

Milling Cutter Measuring System for Edge Width Angle Measurement

Product Application

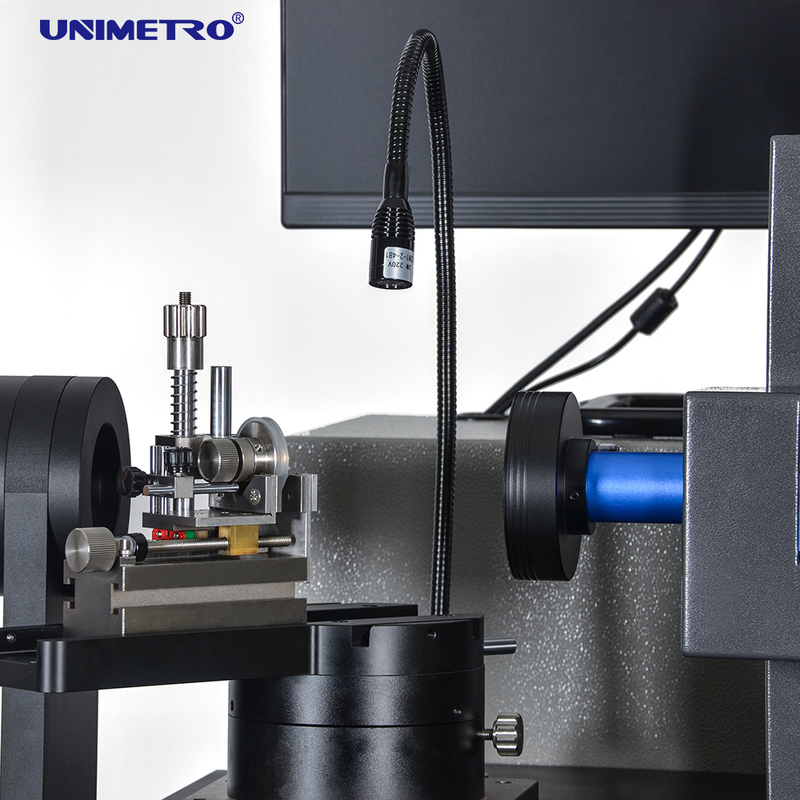

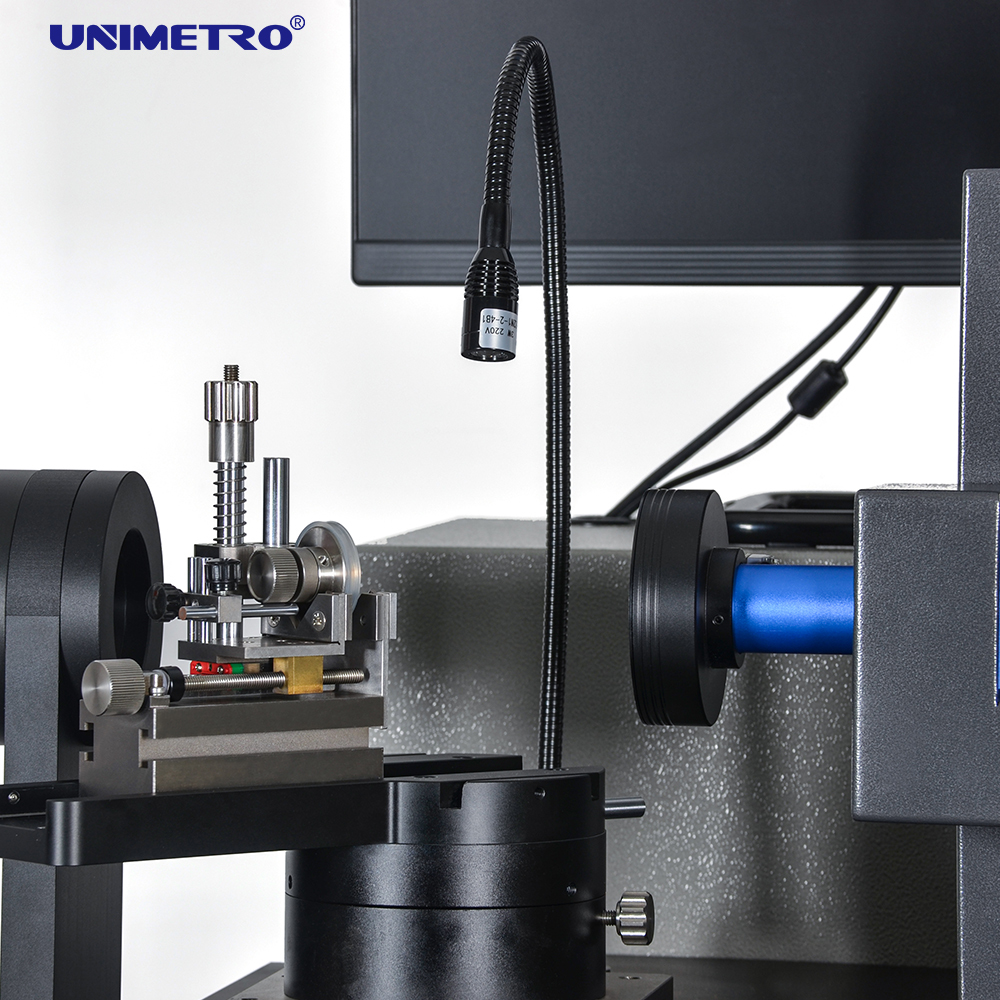

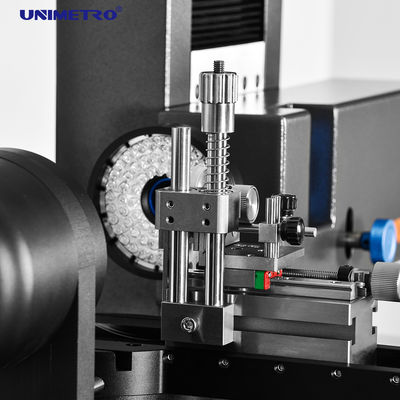

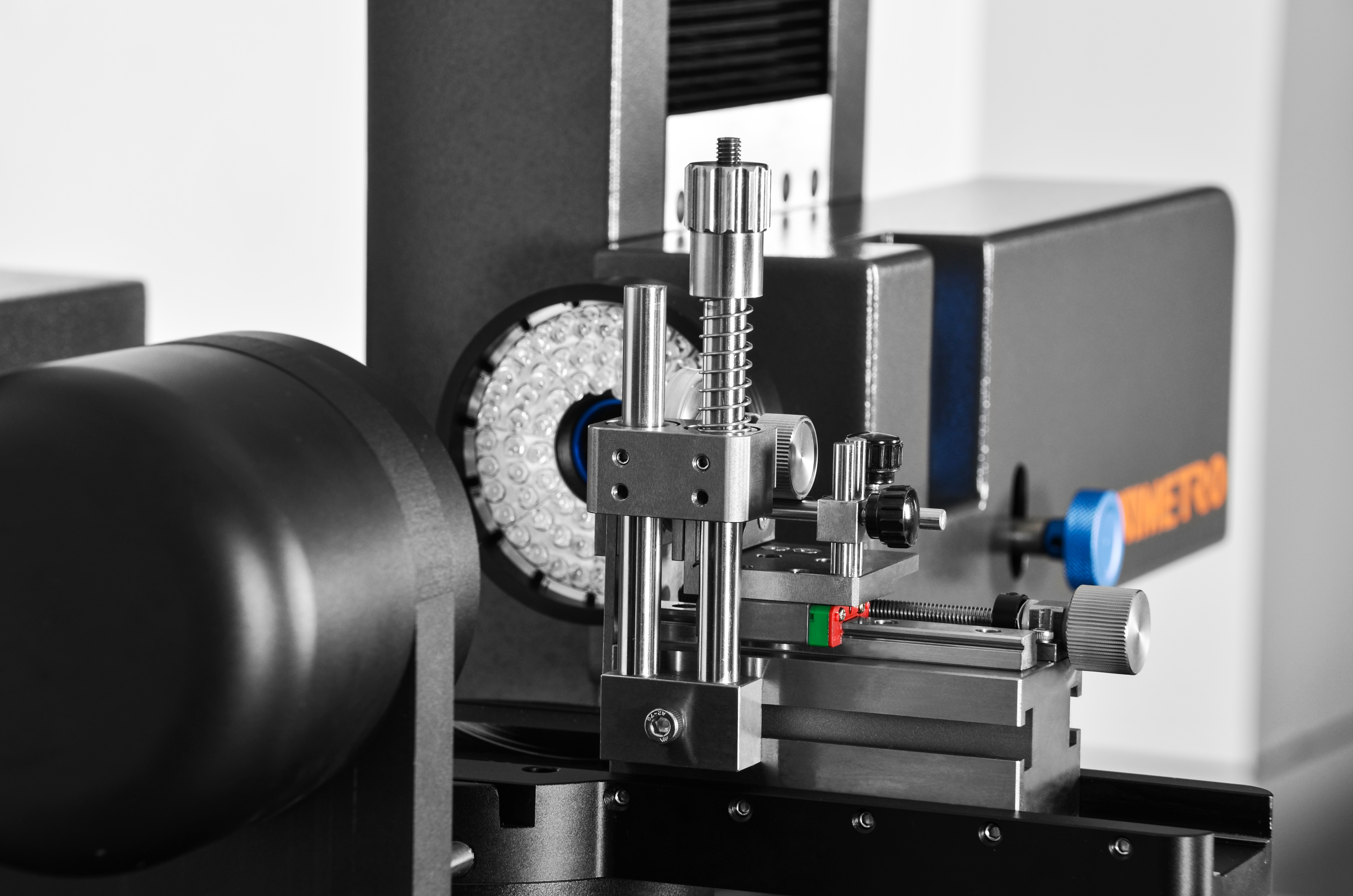

The UNIMETRO RANGER600 Tool Inspection System is a universal measuring machine for drills, milling cutters, and countersinks featuring a flexible illuminating system. Its compact design and exceptional stability make it suitable for metrology rooms, receiving inspection, or direct production use.

Configured with SMARTOOL universal measuring software, the RANGER600 provides comprehensive control of special tool geometries, from simple outer contour checks to complete angle measurements. The system enables a streamlined PUT-MEASURE-ANALYSE process for all types of metal cutting tools.

Technical Specifications

| Parameter |

Value |

| X axis travel |

80mm |

| Y axis Travel |

60mm |

| Z axis measuring range |

60mm |

| Max tool Diameter |

20mm |

| Max tool length |

200mm |

| Working distance |

90mm |

| Lens |

0.7-4.5X dented zoom lens |

| Camera |

2M pixel HD camera/5M pixel HD camera (Optional) |

| Linear scale resolution |

0.0001mm |

| Magnification |

12.6X~79.2X/25.2X~158.4X (Optional) |

| Field of view |

27*20mm~4.3*3.3mm/13.5*10mm~2.3*1.6mm (Optional) |

| Measuring accuracy |

X~Y,(2.5+L/100)µm, L is the measured length |

| PC |

ALL-IN-ONE PC system, Windows 10 OS, with 24" LCD monitor |

| Illumination |

8 sections LED ring light, contour light and flexible auxiliary light, all software control and programmable |

| Input format |

DXF files |

| Output format |

EXCEL,DXF |

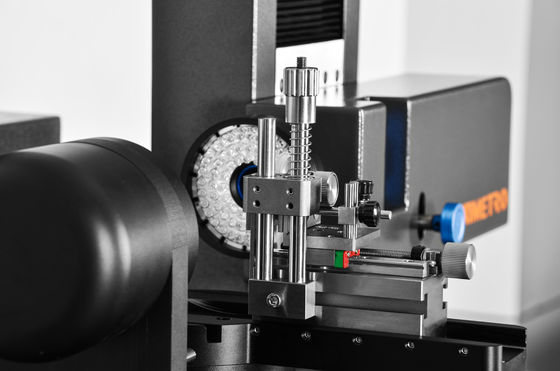

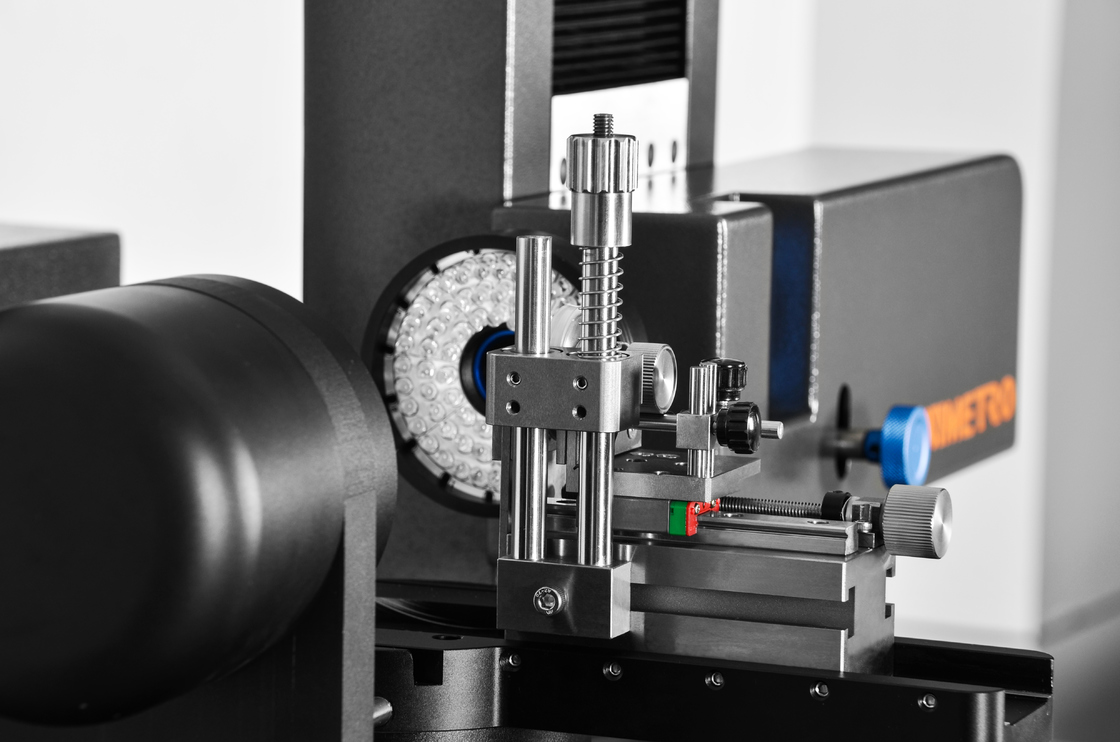

Advanced Design Features

- Ergonomic design with solid construction for stability

- HD image capturing with optional microscope magnification levels

- Stable V-block for secure tool holding and alignment

- Mechanical fixed measuring angles at 0° and 90° on rotary stage

- High accuracy embedded encoder for precise angle location

- Programmable multi-section LED ring light with contour lighting

- SMARTOOL software with specialized cutting tool measurement functions

- Automatic edge detection and CAD element comparison

- Fast measurement output to EXCEL or CAD formats

- Integrated ALL-IN-ONE PC system for enhanced stability

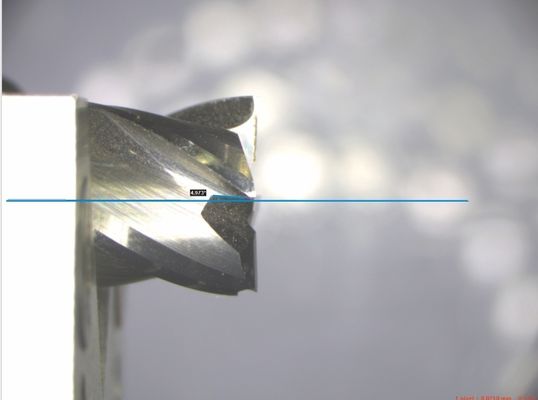

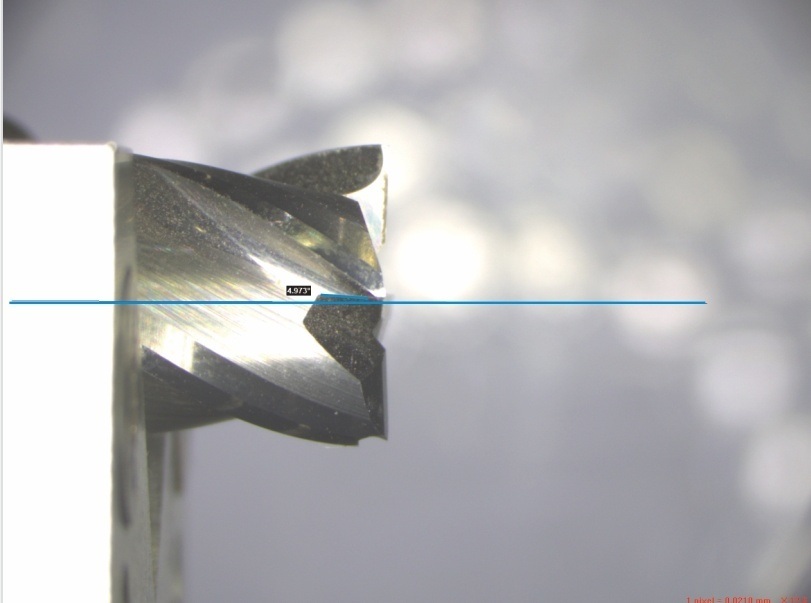

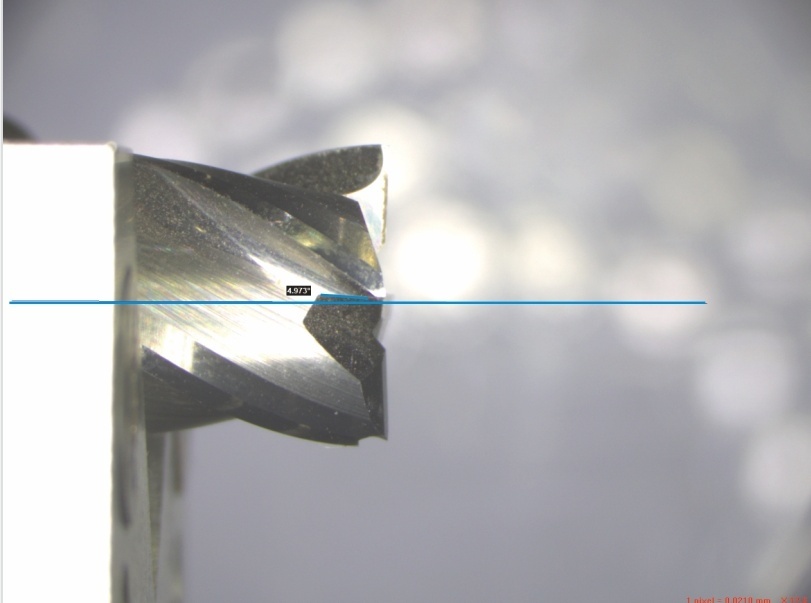

Multiple Angle Measurement Capabilities

The RANGER600's rotary table provides two mechanical fixed angles (0° and 90°) for rapid tool positioning. The 0° position enables measurement of Tool End, Center Shaft, and Front Angle, while the 90° position facilitates measurement of Helix Angle, Axial Front Angle, and Rear Angles. Additional angles can be precisely located using the embedded encoder.

SMARTOOL Measuring Software

The SMARTOOL Cutting Tools Measuring Software combines high-accuracy optical and digital measurement technology with intuitive operation. Developed specifically for grinding applications, it offers comprehensive measuring and evaluation algorithms for manufactured or sharpened tools.

Key Software Features

- High-resolution graphical interface with all controls visible

- Dynamic real-time edge detection curve view

- Rotatable reticle for fast angle measurement

- CAD comparison function for geometry evaluation

- Comprehensive measurement reporting capabilities

Measurement Capabilities

The RANGER600 system provides precise measurement of all critical tool angles and geometries, including:

- Helix Angle

- Axial Front Angle

- First and Second Rear Angles

- Tilting Edge Angle

- Tool End geometries

- Center Shaft measurements

About UNIMETRO

With over 10 years of experience in metrology, UNIMETRO specializes in high-performance measurement solutions at competitive prices. Our product range includes vision measurement machines, coordinate measurement machines, profile projectors, and core optical metrology components.

Our engineering team utilizes Solidworks with FE analysis, AutoCAD/CAM, and industrial 3D printing to deliver rapid prototyping and innovative solutions. We provide comprehensive technical support within 24 hours and maintain a modular design philosophy to minimize after-sales service requirements.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!